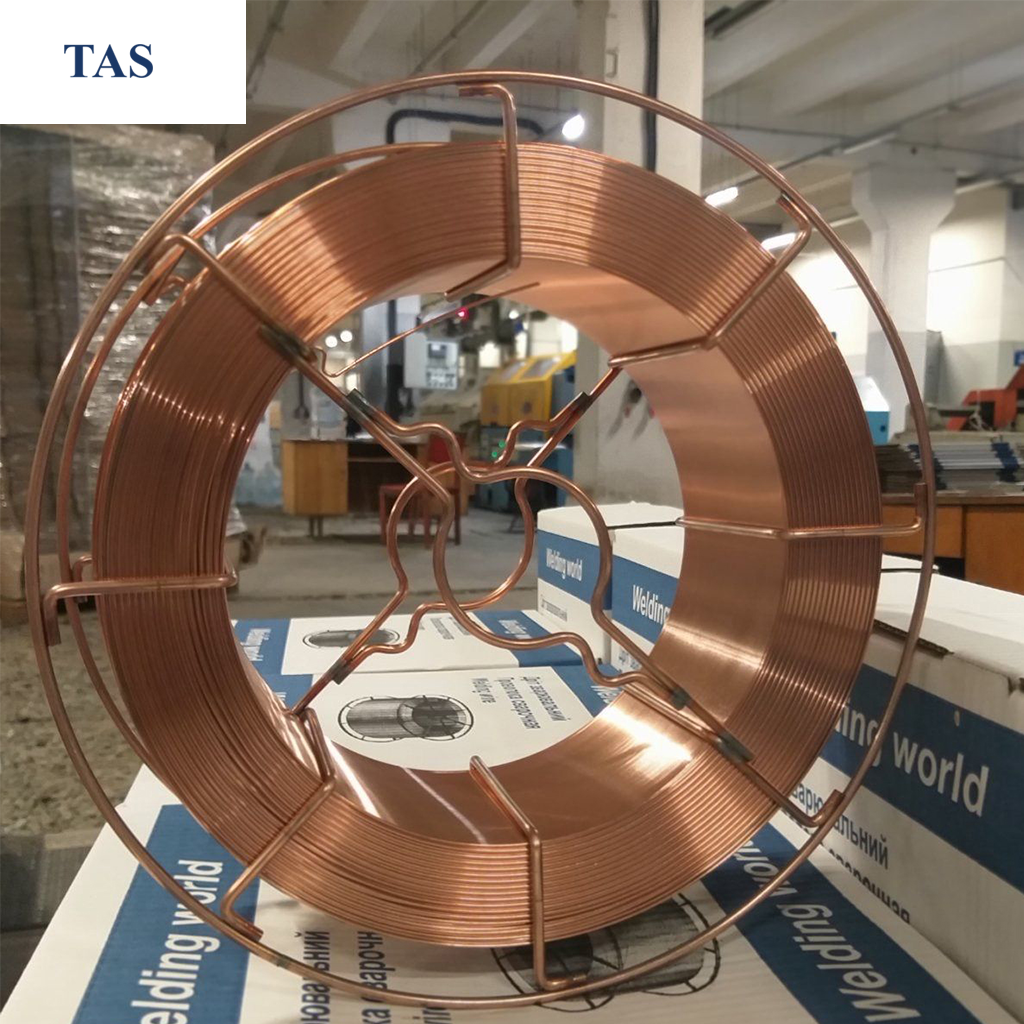

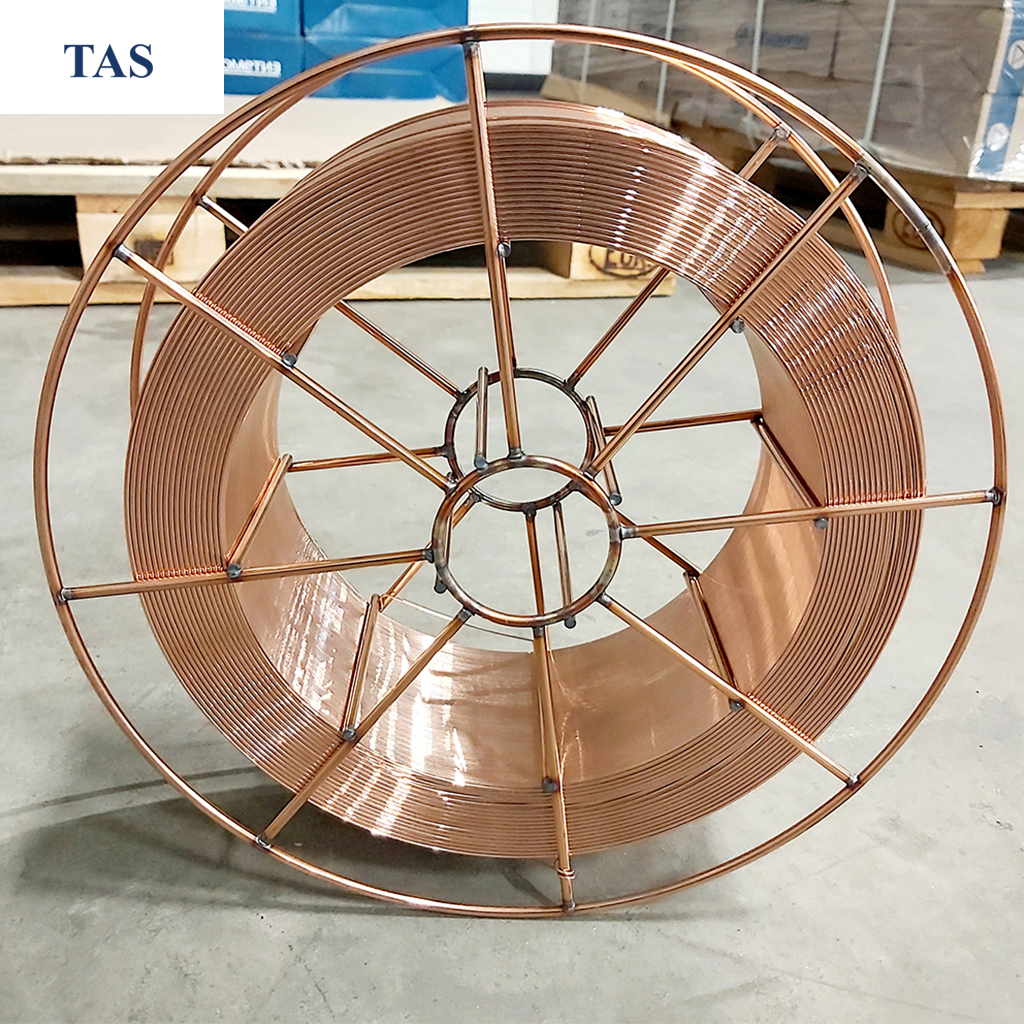

Steel welding wire

Steel welding wire

Wire of grades Sv-08G2S and Sv-08GS is used in shipbuilding, in car building, in boiler building, in assembly work, in construction for welding metal structures, in the automotive industry, in agricultural engineering.

0,8 — 2,0 мм

СВ08Г2С

Wire of grades Sv-08G2S and Sv-08GS is used in shipbuilding, in car building, in boiler building, in assembly work, in construction for welding metal structures, in the automotive industry, in agricultural engineering.

0,8 — 2,0 мм

СВ08Г2С

It is used for automatic and mechanized welding and surfacing of carbon and low-alloy structural steels in a protective gas environment (DSTU EN ISO 14175): carbon dioxide (DSTU 4817), argon (DSTU GOST 10157) and a mixture of carbon dioxide and argon, submerged arc welding (DSTU EN ISO 14174).

It is used for automatic and mechanized welding and surfacing of carbon and low-alloy structural steels in a protective gas environment (DSTU EN ISO 14175): carbon dioxide (DSTU 4817), argon (DSTU GOST 10157) and a mixture of carbon dioxide and argon, submerged arc welding (DSTU EN ISO 14174).

| Wire grade | Wire diameter, mm | Maximum deviations of the wire: | Type of delivery — in coils weight, kg | |

| for welding (surfacing) | for electrodes production | |||

Low-carbon Sv-08, Sv-08А for electrode production | 0,8 | -0,07 | — | 80 |

| 1,0-1,2 | -0,09 | — | 80 | |

| 1,4 | — | 80; 550±50 | ||

| 1,6 | -0,12 | -0,06 | 80 | |

| 1,8-2,0 | 80; 950±100 | |||

| 2,5-3,0 | -0,09 | 80; 950±100 | ||

| 3,5-6,0 | -0,16 | -0,12 | 80; 950±100 | |

Alloyed Sv-08G2S | 0,8 | -0,07 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | -0,09 | — | 1; 2,5; 5; 15; 18; 80 | |

| 1,6-2,0 | -0,12 | — | 15; 18; 80 | |

Copper-coated Sv-08G2S | 0,8 | -0,07 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | -0,09 | — | 1; 2,5; 5; 15; 18; 80 | |

| 1,6 | -0,12 | — | 15; 18; 80 | |

Copper-coated 4Si1 (EN ISO 14341) | 0,8 | -0,04 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | — | 1; 2,5; 5; 15; 18; 80 | ||

| 1,6 | — | 15; 18; 80 | ||

At customer’s demand it is possible to produce wire of the other diameters

Wire grade | Chemical composition, % | |||||||

Mn | C | Si | Cr | Ni | S | P | Al | |

not more | ||||||||

Low-carbon Sv-08 | 0,35-0,6 | 0,10 | 0,03 | 0,15 | 0,30 | 0,04 | 0,04 | 0,01 |

Low-carbon Sv-08А | 0,35-0,6 | 0,10 | 0,03 | 0,12 | 0,25 | 0,03 | 0,03 | 0,01 |

Alloyed Sv-08GS | 1,40-1,70 | 0,10 | 0,60-0,85 | 0,20 | 0,25 | 0,025 | 0,03 | — |

Alloyed Sv-08G2S | 1,80-2,10 | 0,05-0,11 | 0,7-0,95 | 0,20 | 0,25 | 0,025 | 0,03 | — |

4Si1 (EN ISO 14341) | 1,60-1,90 | 0,06-0,14 | 0,80-1,20 | 0,15 | 0,15 | 0,025 | 0,025 | 0,02 |

Wire diameter, mm | Tensile strength, Mpa (kgs/mm2) | |

for welding (surfacing) | for electrode production | |

0,8-1,5 | 882-1323 (90-135) | — |

1,6 | 882-1274 (90-130) | 686-980 (70-100) |

2 | 784-1176 (80-120) | 686-980 (70-100) |

more then 2,0 | 686-1029 (70-105) | 637-931 (65-95) |

| Wire grade | Wire diameter, mm | Maximum deviations of the wire: | Type of delivery — in coils weight, kg | |

| for welding (surfacing) | for electrodes production | |||

Low-carbon Sv-08, Sv-08А for electrode production | 0,8 | -0,07 | — | 80 |

| 1,0-1,2 | -0,09 | — | 80 | |

| 1,4 | — | 80; 550±50 | ||

| 1,6 | -0,12 | -0,06 | 80 | |

| 1,8-2,0 | 80; 950±100 | |||

| 2,5-3,0 | -0,09 | 80; 950±100 | ||

| 3,5-6,0 | -0,16 | -0,12 | 80; 950±100 | |

Alloyed Sv-08G2S | 0,8 | -0,07 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | -0,09 | — | 1; 2,5; 5; 15; 18; 80 | |

| 1,6-2,0 | -0,12 | — | 15; 18; 80 | |

Copper-coated Sv-08G2S | 0,8 | -0,07 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | -0,09 | — | 1; 2,5; 5; 15; 18; 80 | |

| 1,6 | -0,12 | — | 15; 18; 80 | |

Copper-coated 4Si1 (EN ISO 14341) | 0,8 | -0,04 | — | 1; 2,5; 5; 15; 18; 80 |

| 1,0-1,4 | — | 1; 2,5; 5; 15; 18; 80 | ||

| 1,6 | — | 15; 18; 80 | ||

At customer’s demand it is possible to produce wire of the other diameters

Wire grade | Chemical composition, % | |||||||

Mn | C | Si | Cr | Ni | S | P | Al | |

not more | ||||||||

Low-carbon Sv-08 | 0,35-0,6 | 0,10 | 0,03 | 0,15 | 0,30 | 0,04 | 0,04 | 0,01 |

Low-carbon Sv-08А | 0,35-0,6 | 0,10 | 0,03 | 0,12 | 0,25 | 0,03 | 0,03 | 0,01 |

Alloyed Sv-08GS | 1,40-1,70 | 0,10 | 0,60-0,85 | 0,20 | 0,25 | 0,025 | 0,03 | — |

Alloyed Sv-08G2S | 1,80-2,10 | 0,05-0,11 | 0,7-0,95 | 0,20 | 0,25 | 0,025 | 0,03 | — |

4Si1 (EN ISO 14341) | 1,60-1,90 | 0,06-0,14 | 0,80-1,20 | 0,15 | 0,15 | 0,025 | 0,025 | 0,02 |

Wire diameter, mm | Tensile strength, Mpa (kgs/mm2) | |

for welding (surfacing) | for electrode production | |

0,8-1,5 | 882-1323 (90-135) | — |

1,6 | 882-1274 (90-130) | 686-980 (70-100) |

2 | 784-1176 (80-120) | 686-980 (70-100) |

more then 2,0 | 686-1029 (70-105) | 637-931 (65-95) |